Business

Deok-Pyeong Logistics / DPL

TOYOTA FORKLIFT

FULFILLMENT

3PL

LEASE

NETWORK

LOGISTICS

DPL focuses on logistics so that

you can focus on the essence of your business.

FULFILLMENT

IT System (OMS, WMS, TMS)

Packing / Picking / Return

Partners Interface

Couriers Interface

3PL

Bonded / Customes Clearance

Unloading / Storage

Distribution processing

Quality inspection

Transportation, Delivery service

WMS

LEASE

Providing space tailored to

customer needs

Room temperature: 115,702 ㎡

Fixed temperature: 16,529 ㎡

Total 132,231 ㎡

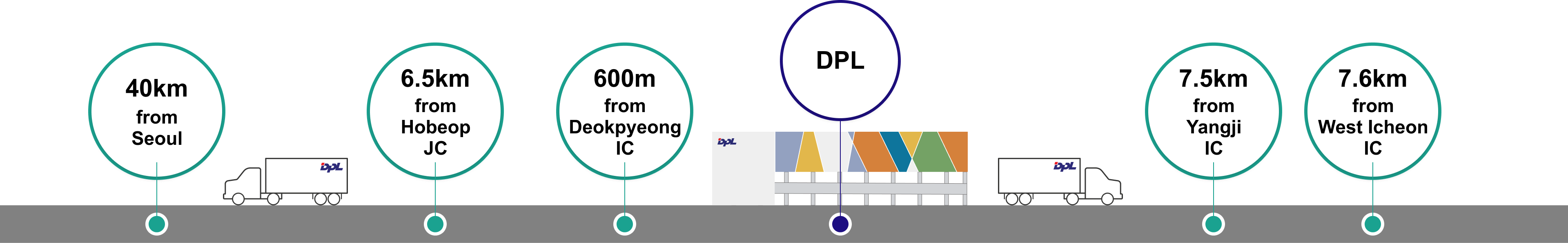

NETWORK

Optimal location close to the metropolitan area

Located within 5 minutes from the highway

FULFILLMENT

DPL constantly thinks about logistics.

As Korea’s leading fulfillment company and a leader in the logistics market,

we are constantly developing and innovating for

the value of logistics and the value of our customers.

Process

Business Optimization

DPL optimizes customers’ operations and enhances productivity through effective

communication.

From domestic and international

logistics to bonded warehouses

DPL’s bonded warehouse, as a self-regulated bonded area, allows for expedited customs clearance according to Article 7 of the Self-Regulated Bonded Area Operation Notice,

which includes omitting the declaration

process for entry and exit of domestic goods.

Keep it safe with the latest

distribution centers and

logistics devices!

Experience premium fulfillment services powered by DPL’s state-of-the-art distribution centers and cutting-edge logistics equipment.

More quickly,

More easily,

More precisely,

DPL offers a comprehensive suite of value-added services tailored to customer needs, including the development and implementation of advanced logistics IT systems. Our expertise extends to end-to-end logistics operations consulting, featuring automated solutions for efficient returns processing and inventory management. Through these integrated services, we deliver optimized supply chain solutions to meet diverse client requirements.

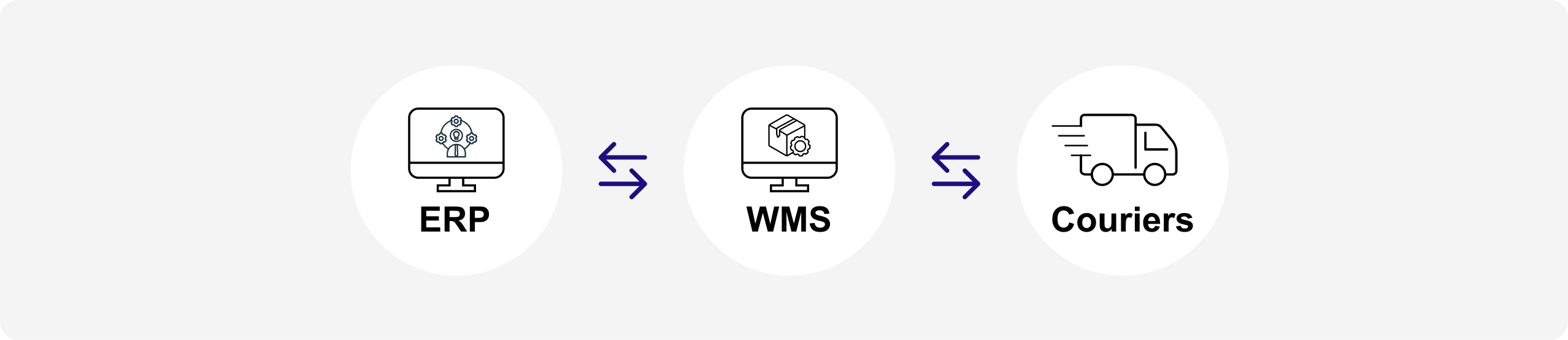

It is also possible to develop a customized interface

that enables information exchange between ERP, WMS, and courier systems.

By utilizing 100% recyclable materials,

DPL supports the ESG management of our customers.

ESG management refers to corporate management activities that

prioritize environmental protection, engage in social contributions

such as supporting the socially disadvantaged, and strictly comply with laws and ethics.

DPL aims to become a socially responsible logistics company

by establishing sustainability guidelines for ESG management.

3PL

DPL grows with its diverse customers.

DPL provides differentiated networks tailored to the characteristics of

each client, and offers optimal logistics services based on accumulated

operational skills and know-how.

Customer Business Areas

Fashion

Cosmetics

Pet food

Snack

Home Appliances

Leisure

Medical Devices

Wine

3PL Scope

Warehousing

Bonded operations

Customs clearance

Quarantine procedures

Storage

Expiration date management

First-in, first-out management

Inventory management

Returns management

Disposal management

Distribution Processing

Repacking

Labeling

Value-added services

Quality inspection

Shipping

Delivery Management

Non-delivery management

Delivery service management

Delivery route management

Vehicle cleanliness management

WMS (Warehouse Management System)

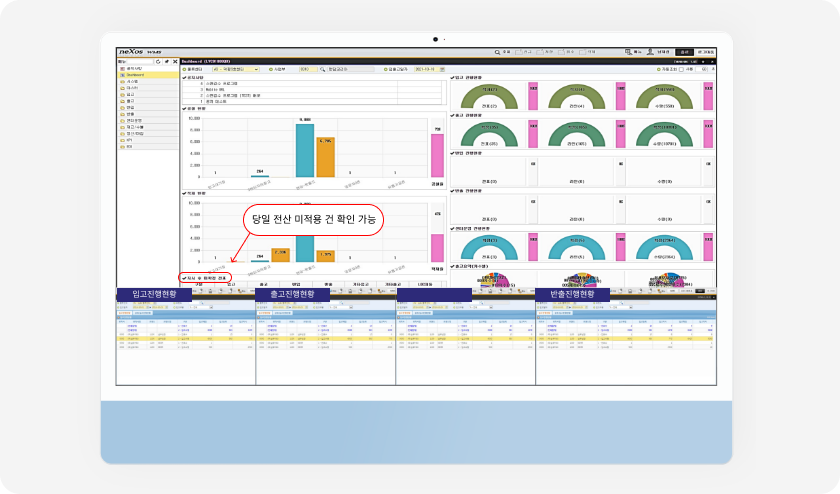

DPL’s Web version WMS was developed with the participation of logistics experts and practitioners.

It is continuously upgraded to improve user convenience and perform various functions.

Inventory Management

First in, First Out and LOT management

Detailed tracking of inbound and outbound operations

Easy inventory management using barcodes

Real-time System

Task processing using PDA and smartphones

On-site processing using mobile devices

Customer service provided via internet

Interface

Interface with shippers’ ERP

Integration with TMS and OMS

Integrated management with DPS and DAS equipment

Monitoring

Provides a service to monitor operation

progress within DPL WMS

KPI

Ability to view and analyze KPI-related data through information

registered in DPL WMS

Information Lookup

Lookup by date/period/supplier/product, label printing function,

PDA inspection date/outbound date, etc.

Inventory Management

Real-time location-based inventory management, Batch management,

Serial Number management, Tracking of inbound/outbound history, etc.

KPI

Turnover rate analysis (overall and by center), Inventory analysis,

Cargo volume analysis, Delivery status analysis, Dashboard

Vehicle Control Lookup

Category-specific lookup function, mobile app, automatic dispatch,

dispatch adjustment, delivery status monitoring

Additional Features

Inbound/outbound work information, interface between IT systems and

equipment Multi-center operation capability, multi-language support, etc.

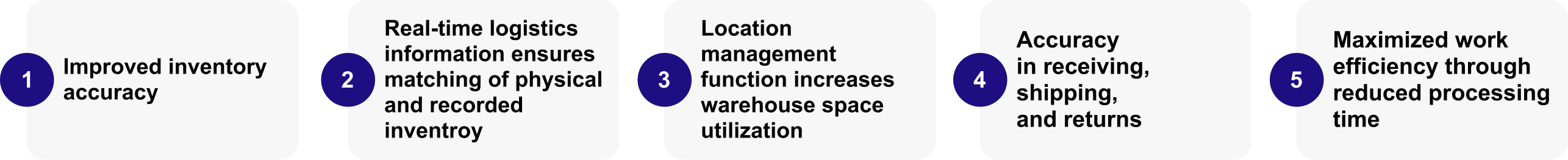

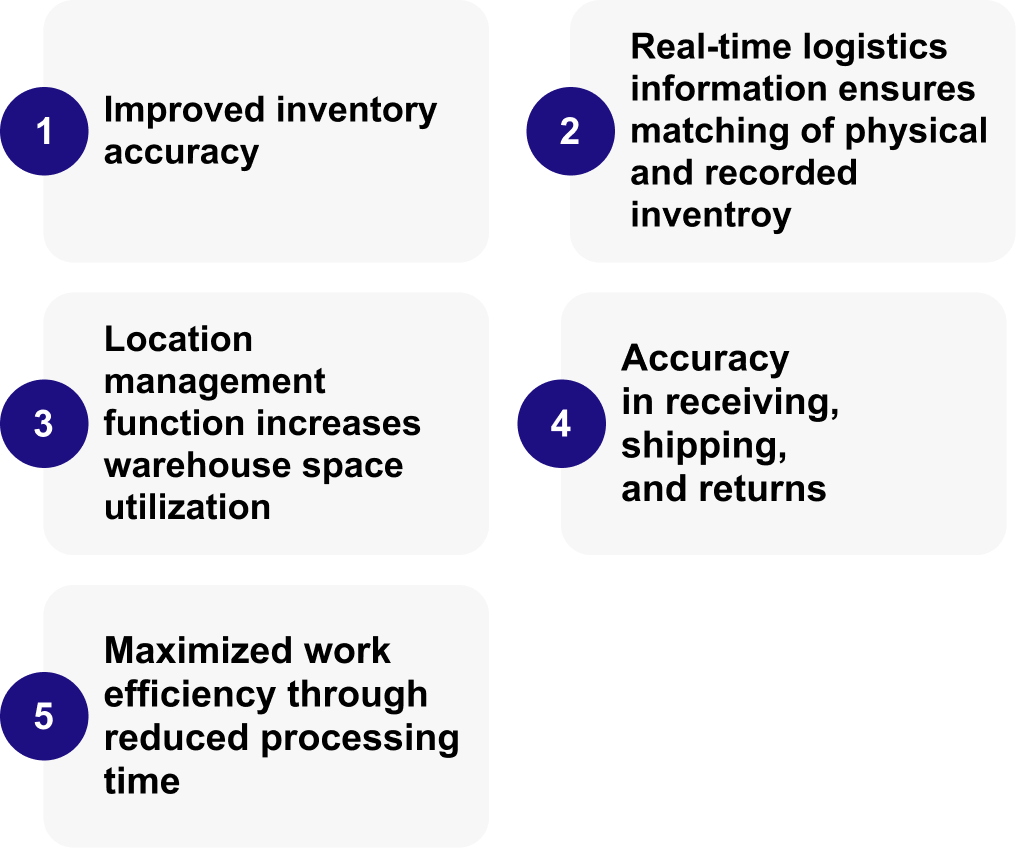

Expected Benefits

Delivery and Distribution

We have established a stable delivery network through the operation of our own forklift in the metropolitan area,

partnerships with partner companies, and collaborations with courier services.

Safety and Reliability

Joint delivery operations with partner companies

Thorough delivery inspections and in-transit recovery processes to prevent claim

Cost-Effectiveness

Delivery management data feedback

Utilized as management information for client companies

Expertise

Professional delivery service provided by specialized delivery personnel

Customer satisfaction training conducted to ensure high-quality delivery services

Speed

Nationwide delivery within 24 hours

Operation of dedicated vehicles for returns, enabling quick collection of returned items

Bonded Services

DPL’s bonded warehouse is designated as a self-regulated bonded area. In accordance with Article 7 of the Public Notice on the Operation of Self-Regulated Bonded Areas, certain procedures – such as reporting the entry and exit of domestic goods – can be omitted. This enables swift customs clearance.

International Logistics

Licensed Customs Broker services

Forwarding

Customs clearance

Customs-related tasks

Bonded Warehouse

Self-regulated bonded area

Temperature control

Inventory management

Transportation

Domestic transportation

Bonded transportation

Contact DPL

LEASE

DPL knows what you need.

We operate 5 hub logistics centers based on optimal locations adjacent to

the metropolitan area, and we have various types of

logistics centers to meet our customers’ needs.

Advantages of DPL Center Rental

Prime Location: Centered in Icheon, a transportation hub close to the metropolitan area within 5 minutes of highway access.

Temperature-Controlled Center:

33,000 m² facility adjacent to the metropolitan area

Indoor temperature control units

Unit cooler control panel

Temperature status within panels

Fire shutters

Temperature maintenance facilities

Dedicated distribution centers for each product type, such as clothing / wine / medicine / cosmetics, etc.

DPS

DAS

RACK

Mezzanine

Air conditioning system

24/7 manned/unmanned security system

24-hour manned security

CCTV

Monitoring

Security card access system

Fully equipped facilities and systems for initial fire response:

Fire detection sensors

Fire alarms

Indoor fire hydrants

Outdoor fire hydrants

Emergency lighting

In-house alarm system

Offices and distribution processing areas located within the logistics center for

convenient operation management

Sorting

Promotional set/bundle products

Repackaging

Labeling

Contact DPL

NETWORK

DPL is dedicated to exceeding

your expectations.

We strive to provide the best facilities for safe storage,

ensuring your peace of mind.

Temperature-controlled /

Bonded center

3PL (1st floor), Rental (2nd, 3rd floors)

Temperature control equipment / Temperature and humidity management (1st floor) / Bonded area

Sprinkler system (all floors)

24/7 operation of motion sensor CCTV

365-day manned security, unmanned security

Hoeuk Center

Fulfillment / Bonded center

3PL (B1, 1st floor), Rental (2nd floor)

Room temperature center / Firewall separation / Bonded area

Sprinkler system (all floors)

24/7 operation of motion sensor CCTV

365-day manned security, unmanned security

Kwan-ri Center

Room temperature center

3PL (2nd, 4th floors),

Rental (B2, 1st floor)

Room temperature center / Multi-level structure

Sprinkler system (all floors)

24/7 operation of motion sensor CCTV

Unmanned security

Baeksa Center

Clothing-exclusive center

3PL (4th floor), Mezzanine (3rd floor)

Room temperature center / Rack + Mezzanine structure

Sprinkler system (all floors)

24/7 operation of motion sensor CCTV

Manned security, Auto conveyor equipment , Automatic packaging machine

Anseong Center 1

Room temperature /

Fulfillment center

3PL (1st floor)

Room temperature center / Firewall separation / Rack structure

Sprinkler system (all floors)

24/7 operation of motion sensor CCTV

Unmanned security

Anseong Center 2

Room temperature / Bonded / Fulfillment / Clothing-exclusive center

Designed to LEED SILVER LEVEL

(Scheduled for completion in July 2026)

DPL Network Environment

ESG management and LEED certification (planned)

Creation of comfortable operating and

working environments

Compliance with fire safety laws and

operation of separate equipment/facility teams